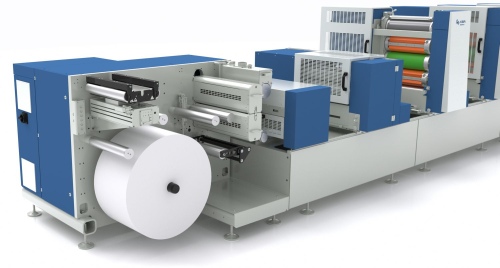

Another component in the product portfolio from KBA-MePrint AG. After years of experience as an innovative provider of proven solutions for plastic, paper and cardboard printing, we have taken the next step with a semi-rotary narrow web offset printing machine. With the new, innovative Varius LX-TX, KBA-MePrint AG opens up the advantages of waterless offset printing to demanding users of label and laminate printing applications.

Unrivalled technology

The Varius LX-TX is a modular roll machine for printing high-quality labels and dimensionally stable laminates. The printing machine is equipped with proven printing technology from KBA-MePrint AG, which has always stood for brilliant print quality, maximum flexibility, and high performance.

The Varius LX-TX is the perfect device for producing high-quality labels for the wine, cosmetics and spirits markets as well as for printing tube laminates

At a glance:

- Fast job change

- Significantly lower paper waste (up to 90% less)

- Minimal setup times due to automatic plate Change

- Faster job and format changes — no change of sleeves or cassettes needed

- No adjustment of colour zones

- Waterless printing system, no dampening system, no dampening solution additives, less volatile organic components (VOC)

- Multi-colour printing in photo-realistic print quality

- Excellent reproducibility of repeat jobs due to the small number of process Parameters

- High, consistent print quality through the entire print run

- Consistent colour reproduction and high colour brilliance

- No ghosting

- Fast, easy to learn operation

- Economical and competitive for small to medium print runs

Modular multi-platform technology

In addition to the base technology – waterless offset printing — additional printing methods, finishing and processing steps can be integrated. The Varius LX-TX is designed so that in addition to KBA anilox short inking technology, waterless offset printing with long printing units, flexo printing for UV coating and opaque white applications, and KBA Kammann flatbed screen printing technology can be used.

The concept of the Varius LX-TX provides the customer with an individual, tailor-made solution for finishing and further processing. The large number of modules that can be integrated into the machine means maximum flexibility (e.g. cold and hot stamping, embossing, stamping, cutting, weeding, etc.). Digital print heads for identification, individualisation and personalisation can also be implemented.

Depending on customer requirements, a wide range of drying systems from different manufacturers are used. In addition to drying with ultraviolet and infrared radiation, a hot-air dryer system can also be installed.

The semi-rotative printing process makes possible continuous variation of the printing length without changing the plate and blanket cylinder.

A high degree of automation (fully automatic plate change, auto register, optional quick-change doctor blade chamber) greatly minimises set-up times.

The modular design of the machine makes possible customer- and application-specific configuration of a production line. This ensures that future market and product requirements can also be fulfilled at any time.

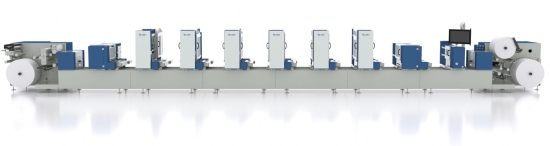

Example configuration of a Varius LX-TX (left to right): Unwinding unit – Infeed unit – Flexo printing unit (priming) – 6 Offset printing units – Flexo printing unit (varnishing) – Rotary die-cutter – Pulling unit – Winding unit