“We used to think that the Internet would destroy the printing industry”, ponders Jeff Pallis, President and CEO of DS Graphics in Lowell, Massachusetts. “But in reality, it isn’t destroying our industry, it’s simply changing it. The Internet has opened up many new market opportunities for our company”. Happily, that is reflected in the bottom line of the family-run business. While its conventional print business contracted by around 10 percent last year, DS Graphics recorded growth of between 15 and 20 percent in the new markets over the same period. “Thanks to the new markets, 2015 was the most profitable business year in the history of our company”, notes Jeff Pallis.

Variable data printing is one of the business segments that is experiencing most marked growth at DS Graphics. “Our work is increasingly focused on databases, allowing customers to be targeted more effectively using customized catalogs”, says Jeff Pallis. “That has three major advantages. Our customers save money because they can avoid distribution losses. Our end customers save time because they only receive advertising that they are really interested in. And for us it’s an attractive business model. In short, it’s a classic win-win-win situation”.

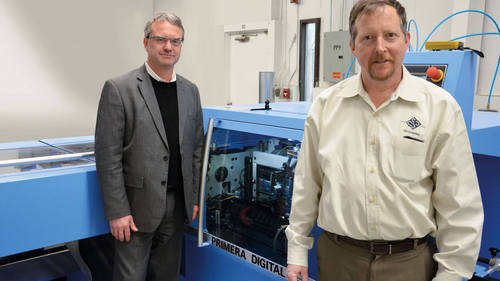

Carrying out the (digital) printing of all these customized and personalized products such as mailings, manuals, various directories and many other marketing products is one thing – efficient print finishing however is a completely different matter. “The major challenge is to achieve a high production speed in finishing too”, says Jeff Pallis. For saddle stitching, DS Graphics therefore relies on a Muller Martini Primera Digital. According to Jeff Pallis, the same goes for machines and customer requests today: “Our customers want customized print products, and we’re looking for tailored machine solutions”.

Vareo – the Ideal Perfect Binder for Runs of One Copy

DATEV in the German city of Nuremberg has been producing products in runs of one copy for two decades now. However, technological developments in its core business field have never benefited the German pioneer in that market segment as much as they do today. First, digital systems greatly simplify the industrial printing of lot sizes of one copy. Second, DATEV now has a perfect binder that is ideally suited to the company’s product range – each of the Vareo’s three clamps is equipped with its own servo motor and each clamp is individually driven.

Until a few months ago DATEV used three ultra-small perfect binders of another manufacturer for its short-run products. Those machines were replaced by a Vareo. Its high degree of automation, true to Muller Martini’s “Finishing 4.0” drupa catchword, was the main reason for the investment, since it means the operators no longer have to keep on performing changeovers manually. “We’ve been able to shorten our lead times considerably”, says Robert Gebhard, Design and Distribution Team Leader at DATEV. “We believe the Vareo technology has great potential, and we’re already developing new softcover products for our customers”.

Solutions Are Needed, Not Just Machinery

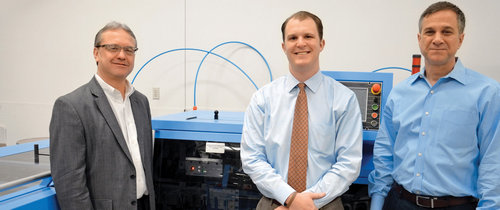

Complex products, whose components often come from three different printing sources, are also a specialty of Allied Printing Services, Inc. in Manchester in the U.S. state of Connecticut. Content signatures are printed using web offset, and covers using sheet-fed offset. They are joined by digitally printed elements, such as whole four-page signatures or affixed personalized coupons, whose address corresponds to the address printed on the back cover. “Print will always play an important part in communications”, says CEO and President John G. Sommers Jr. “However, we need to handle data optimally because the market has become much more sophisticated and data-based. Our customers want to appeal to their readers with targeted print products”.

Since such products call for smart production, Allied relies on a Muller Martini Primera with a Fastech inkjet and camera monitoring system. The Asir 3 system of the saddle stitcher ensures that the signatures, which feature barcodes, are in the correct sequence and the stitched products are complete. “Muller Martini has greatly helped us to accelerate our workflow”, says Jonathan S. Kaufmann, Senior Vice President Technical Development. “Today complete solutions are called for, rather than just machines”.