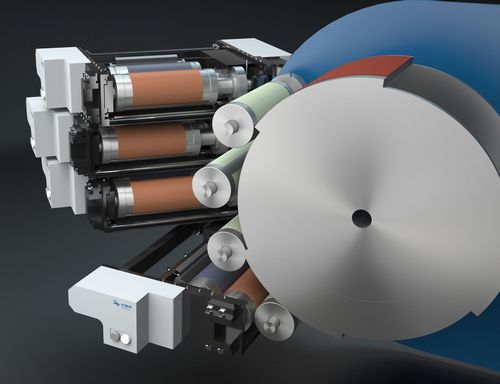

KBA-MePrint AG provides an interesting new development in the form of an innovative printing alternative for the growing market of tube decoration. The printing unit offers a simple design and just a few rollers. By integrating the short inking unit into an existing round-body printing system, printing onto plastic tubes enters totally new dimensions in terms of printing technology.

Less is often more

The system works without ink zones and without dampening system and quickly applies the ink to the round body. A significant portion of the set-up work, such as the time-consuming adjustment of the colors zones, is thus no longer necessary. The temperature of the plate cylinder and screen roller is controlled in order to stabilize the printing process. This ensures uniform, constant and reproducible production. The printing unit offers easy handling and high reliability.

At a glance:

- Multi-color printing in photo-realistic print quality

- Excellent reproducibility of repeat jobs due to the small number of process parameters

- Minimal setup times and low startup wastage

- Lower costs for printing plates compared to printing blocks

- Low maintenance costs with few wear parts

- High, consistent print quality through the entire print run

- Consistent color reproduction and high color brilliance

- Exact drawing details including the finest color nuances

- High dot definition with no ghosting

- 1:1-color transfer using identical cylinder diameters eliminates ghosting

- Fast job change

- Fast, easy to learn operation

- Economical and competitive for small to medium print runs

Add success to the equation today!

By upgrading to a waterless inking unit, compared to comparable technologies, the printing unit is inked up more quickly. And the best part: You save up to 95% of your waste! For users who put a premium on flexibility in their work and have frequently job changes, this is an important source of savings. In the lower and mid-range volume sectors, significant cost advantages arise. Environmental performance is another key aspect: printing is performed without water, solvents or powders.

Small effort, big impact

Is it your goal to further improve your performance, flexibility and profitability?

We know what's important to users in the tube decoration sector. Using our expertise, technology and reliability, we want to accompany and support you to use new printing technology. Completely new fields of application open up when using of our novel short inking unit. The low setup costs, short changeover times and, in particular, the low waste help to ensure quick amortization of the conversion costs.

A well-rounded approach

With the innovative waterless printing unit for high-quality decoration of plastic tubes, KBA-MePrint AG is able to penetrate the packaging market with excellent print quality and unrivalled productivity and profitability. In particular with time-consuming and expensive spot-color motifs, ambitious users can make an impression with end users.